Electric power is something we all depend on, daily. Behind many machines, systems, and building operations are industrial electrical transformers and good support from an electrical parts supplier. These two help ensure electricity is delivered safely, efficiently, and reliably. In this article, you will learn what industrial electrical transformers are, how they function in everyday settings, how to choose them well, and why the relationship with an electrical parts supplier is so important. We’ll keep the language simple and use examples you can relate to.

What Are Industrial Electrical Transformers?

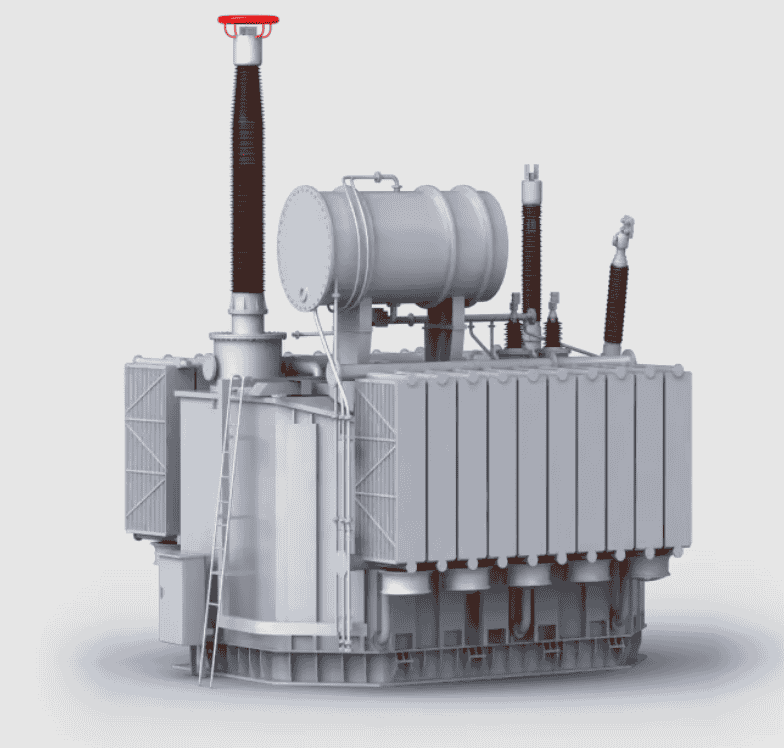

Industrial electrical transformers are heavy-duty machines used in factories, large buildings, plants, and any facility where large or powerful electrical equipment runs. Their job is to change (step up or step down) voltage levels in order to match what the equipment needs or to make distribution more efficient. Without proper voltage matching, machines could under-perform, overheat, or get damaged.

These transformers consist of metal cores, windings (coils of wire), insulation, cooling mechanisms (air, oil or other), and protective components. In industrial settings they are built to take large loads, sometimes 24/7, and deal with rough environments—heat, dust, vibration, or moisture.

How Do Industrial Electrical Transformers Work—Simply Explained

To understand how these transformers operate, imagine a water system: you have water flowing through pipes. If the pipe is narrow and water pressure is high, there’s loss, risk of bursting. If it’s wide enough, things flow smoothly. Electrical voltage is like pressure; current is like water flow. Transformers adjust the “pressure” so power moves efficiently and safely.

Inside, when alternating current enters through primary windings, it produces a changing magnetic field in the core. That changing field induces current in the secondary windings. The ratio of turns (loops of wire) between primary and secondary defines whether you get more voltage out, or less. If more turns in secondary than primary, you step up; fewer, you step down. Efficiency depends on how good the core material is, how well it’s cooled, and how well it’s insulated.

Where Industrial Electrical Transformers Are Used

You see industrial electrical transformers in many places, even if you don’t notice them. In a large factory, they enable heavy motors, furnaces, pumps, or presses to run at their required voltage. In commercial-industrial buildings, lighting, air conditioning, power distribution need them. On large campuses or processing plants, multiple voltage zones are needed: incoming supply might be a high voltage; machines need a lower one. Transformers bridge that gap.

They are also used when power needs to travel far: stepping up voltage for long distance transmission reduces loss; then stepping down near use points. They are critical in mining operations, in steel mills, in large workshops, in cold storage units, and in any place where power demands are large or varied.

Why a Good Electrical Parts Supplier Matters

Having reliable industrial electrical transformers is not enough. The supporting parts matter a lot—coils, insulation, cooling components, protective hardware, connectors, etc. That’s where an electrical parts supplier comes in. A good supplier ensures that the parts you get match the specifications, are high quality, are available when needed, and are safe.

When the electrical parts supplier has experience with heavy-duty transformers, they understand what insulation class you need, what cooling style works best, what tolerances are acceptable, and what certifications are important. They help avoid mismatches (wrong voltage, wrong size), delays in repair, and unsafe installations. In many plants, downtime cost is high; having parts on time can mean the difference between minimal interruption and major losses.

Important Features to Look for in Industrial Electrical Transformers

Choosing the right transformer means matching design and function to real use. Some important features to evaluate are:

-

Capacity: what power rating you need now and possibly later. A transformer that’s too small will struggle; too big may cost more upfront and occupy more space.

-

Voltage levels: both input (from the grid or upstream supply) and output (to equipment) should align correctly.

-

Cooling type: oil-immersed versus dry or air-cooled types. Conditions like temperature, enclosure, fire risk dictate what cooling and insulation style is safe.

-

Insulation and materials: good materials resist moisture, heat, electrical stress. Insulation aging can cause failures.

-

Protection features: overload protection, surge protection, grounding, safety devices. These reduce risk of damage or fire.

-

Physical installation environment: indoor/outdoor, space constraints, exposure to dust or moisture, vibration. That affects size, casing, mounting, protection ratings.

-

Efficiency and losses: look at how much energy is lost in normal operation. Higher efficiency often means lower operating costs over time.

A trustworthy electrical parts supplier should help you evaluate all those features, perhaps provide options, suggest what matches best for your setting rather than pushing whatever’s in stock.

Common Issues & How to Prevent Them

Even well-built units face wear and problems. Being aware helps.

Overheating is often caused by overloads, blocked cooling, or loose connections. Moisture ingress harms insulation; insulation breakdown causes short circuits or arcing. Voltage surges damage windings. Poor maintenance causes small issues to escalate. Repairs delayed because parts not available or mismatched. Installation errors—wrong orientation, inadequate supports, poor grounding—cause mechanical or safety issues.

To prevent those: ensure correct sizing, maintain clean environment, schedule inspections, use proper cooling and ventilation, monitor temperature and voltage, use surge protection, keep spare parts ready from a reliable electrical parts supplier.

Relatable Example: Workshop & Cold Storage

Picture a cold storage warehouse in a region with hot summers. It has large refrigeration compressors, lighting, fans, and control panels. When power supply enters the facility, voltage is high; machines need lower. An industrial electrical transformer steps down the voltage. Because ambient temperature is high, transformer has strong cooling, oil‐filled insulation. The electrical parts supplier you choose provides durable insulation sleeves resistant to oil and heat, reliable connectors, and timely replacement parts. When one fan motor heats up and trips transformer protection, quick repair with correct spares avoids spoilage of food.

Now think about a metal workshop adding welding machines. Welding machines draw heavy current at start. The workshop upgrades to a transformer with good overload capacity. They also source spares for bushings, insulation, terminals from an electrical parts supplier who knows heavy-duty specs. This reduces breakdowns, improves safety, and keeps work running without long stoppages.

Benefits of Proper Selection and Maintenance for Industrial Electrical Transformers

Proper choices and upkeep bring real advantages. Here are benefits:

-

They last longer and give reliable service, reducing surprises and costly downtime.

-

Power delivery is stable, so machines run well and safely; you avoid failures due to voltage swings or overloads.

-

Operational costs drop because fewer losses, less wasted heat, fewer breakdowns.

-

Safety is improved: fewer faults, less risk of fire or electrical accidents.

-

Total cost over time is lower: even if initial cost is higher, better parts and correct specifications reduce repair, replacement, and energy costs.

Emerging Trends & What to Watch For

The field of industrial electrical transformers is also changing. Some of the newer trends include monitoring and diagnostics built into transformers so you can see health status (temperature, vibration, insulation resistance). Better core materials to reduce losses. Eco-friendly insulating materials and oils. Modular designs where parts can be replaced easily. Remote or predictive maintenance using sensors and alerts. Also, better coordination between transformer manufacturers, users, and electrical parts supplier networks so that spares are standardized and easier to get.

Conclusion

Industrial electrical transformers do foundational work: converting voltage, protecting machines, ensuring efficiency and safety. But they don’t work well in isolation. Having a good electrical parts supplier who understands heavy use, environment, quality, and timing matters just as much. Whether you are managing a facility, upgrading systems, or simply maintaining existing equipment, knowing what features matter, common pitfalls, and where to get reliable parts can make a big difference. With proper selection, care, and support, your transformer system can serve for many years with less worry.

FAQs

Q1: How often should industrial electrical transformers be serviced or inspected?

Ideally, at least once every year for basic checks (temperature, connections, insulation). In harsher environments (high humidity, dust, heavy load), inspections every 6 months or even quarterly might be wise.

Q2: What questions should I ask an electrical parts supplier when buying spares?

You should ask about the exact specifications (voltage, capacity, insulation class), compatibility with your transformer model, material quality, lead time for delivery, warranty, and whether the parts are standardized or custom.

Q3: Can a transformer work properly if I use lower grade parts from a cheaper supplier?

Using lower grade parts may work in the short term but risks include premature wear, overheating, reduced efficiency, safety issues, and more frequent failures. Often, what seems like savings ends up costing more due to downtime and repairs.

Q4: Is it better to oversize an industrial electrical transformer “just in case”?

Oversizing gives safety margin, especially for future load growth or occasional spikes. But too much oversizing can waste money (higher upfront cost), take more space, and may reduce efficiency under low load. It’s best to size reasonably with some buffer rather than going far above needs.